|

|

|

|

How do you know if things are OK or not? Go and check them is the

answer - but obviously you can't do it all by yourself? TPI's new

Pocket Inspection system allows absolutely anybody to do it for you

by simply answering a list of customizable user defined questions on

a rugged handheld PC. The answers are stored and uploaded to the

included PC trending software that automatically flags up any

warnings or alarms. It will even send out emails to anyone who needs

to know! The handheld Pocket Inspection unit is Extremely rugged (waterproof

and droppable) and has a high resolution color display with both

touchscreen and keypad entry capability. The software is incredibly

easy to use and set up. It comes with a set of "industry standard”

inspection menus (e.g. fan inspection, pump inspection, etc) that can

easily be edited to create new user defined inspection metrics, or

simply create your own. "Is the floor clean?", "Are the lights working?"

and so on…

Consistent verifiable inspections are often the difference between a

long life span and early failure. With the optional RFID feature the

entire inspection process can be automated. The addition of RFID tags

enables instant recognition of individual assets. Customizable menus

guide field technicians through a checklist to ensure consistent

inspection parameters each and every time. Pocket inspection will also

write data back to RIFD tags so the inspection is verified. Data

gathered in the ruggedized PDA is automatically downloaded to the

correct file when synchronized with the host computer to eliminate

data entry errors. Reports can be generated quickly and emailed

automatically to managers and technicians so little problems can be

dealt with before they become big headaches. Applications Include:

• Commercial / Industrial HVAC

• Food Processing

• Manufacturers

• Mining

• Packaging

• Petrochemical

• Printing and Paper Processing

• Utilities

Includes:

Trimble Nomad, Carrying case, C-Trend Software, Mobil Inspect and Network

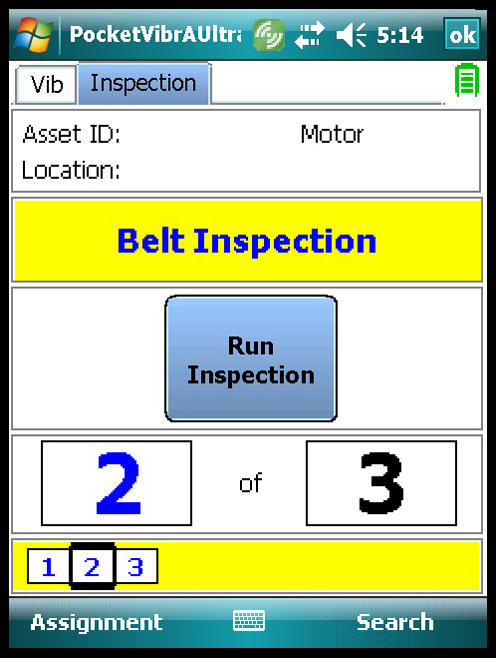

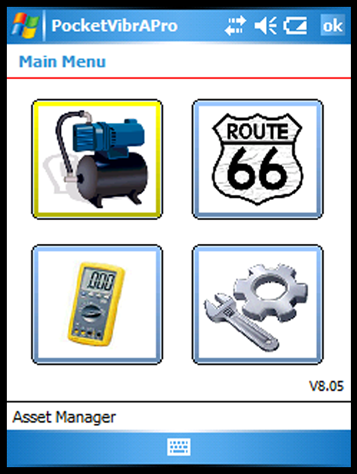

Screenshots:

DOWNLOAD DATASHEET DOWNLOAD DATASHEET

| Size |

8.7” x 3.7” x 1.8” (220 mm x 95mm x 45mm) |

| Weight |

1.1 lb (500g)(not including accelerometer) |

| Environmental |

Water: MIL-STD-810F, Method 512.4

IP67 sealed against accidental immersing

(1m for 30 min)

Drop: MIL-STD-810F, Method 516.5, Procedure IV

26 drops from 1.22 m

6 additional drops at -4°F (-20°C)

6 additional drops at 140°F (60°C)

Operating: -22° to 149°F (-30° to 65°C)

Storage: -40° to 158°F (-40° to 70°C)

Humidity: MIL-STD-810F, Method 507.4

Sand and Dust: IP67, Mil-STD-810F, Method 510.4,

Procedures I and II |

| Power Supply |

Rechargeable battery (charger included) |

| Battery life |

Typically 8-20 hours operating time

depending on backlight usage. |

| Numeric Keypad or Touch screen operation |

Stylus free collection of vibration data using single key

press or touching screen |

| Accessories |

• Carrying case with neck strap

• Stylus lanyard

• Docking Station |

|

|

|

|

|

|

|