|

The TI-MVX offers a series of advanced features including A-Scan, B-Scan as well as a complete alphanumeric datalogging system with storage capacity of thousands of data values and A-scan captures. The TI-MVX features the highest resolution graphic LCD on the market and is especially engineered for optimal ease of use. It is supplied as a complete kit with all accessories in carrying case with FREE software, transfer cable and NIST-Traceable Calibration Certificate.

The MVX is equipped with multiple viewing options to provide users with a complete set of inspection tools: (RF waveform, +/- Rectified waveform, Time based B-Scan, and Large Digits). The A-Scan rectified mode is commonly used for detecting flaws/pits in pulse-echo mode and measuring through paint and coatings in echo-echo mode. The time-based B-Scan feature of the MVX displays a cross section of the test material. It is commonly used to display the profile of the bottom surface of the test material. Built in hardware AGC gain control for through paint measurements in multi mode operation. The MVX has the ability to store 64 custom user defined setups. All factory setups can be selected, edited and saved to any setup location. Use the visual alarm to set hi and lo limits for applications requiring specific tolerances. If the actual thickness value is above or below the limits, a red light is illuminated. Use the find feature to locate the detection point, while automatically adjusting the display to bring the signal into view. MVX also comes complete with our Windows® PC software for transferring data to and from a PC.

Includes Flaw Inspection - Prove Up Mode, (special probe required) The high speed scan feature speeds up the inspection process by making 32 measurements per second. Remove transducer from the test material, and display the minimum measurement scanned. CE Certified Includes NIST Calibration Certificate Display Views

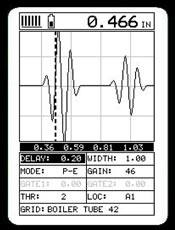

A-Scan Scan Mode

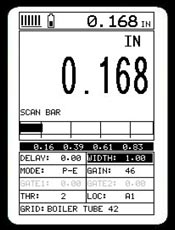

B-Scan Mode

Large Digits

The A-Scan rectified mode is the preferred

display view for flaw and pit detection applications

and measuring through paint and coatings in the

echo-echo mode.

The B-Scan view displays a time-based cross

section of the test material. It is commonly used to

display the profile of the blind or underside of a pipe

or tank.

The Large Digits view provides a

basic digital thickness gauge look and feel. The large

display makes it easy for the operator to monitor the thickness readings.

The TI-MVX is supplied as a complete kit with

note: sensor probe not included with this model

Gauge 4 oz. bottle of coupling fluid 2 AA batteries NIST Calibration Certificate Data transfer software Serial output cable Operating Instruction Manual Foam-fitted carrying case

Download User Manual Download User Manual

-

Range in Steel*:

-

Pulse-Echo Mode: Pit and Flaw detection measures from 0.63 to 254 millimeters (0.025 - 9.999inches)

-

Echo-Echo Mode: Thru Paint & coatings measures from 2.54 to 102 mm (0.1 - 4.0 inches). Range will vary +/- depending on the thickness of the coating.

*Range varies by transducer, multiple transducers are required to cover entire range

-

Resolution: .001 inches (0.01mm)

-

Velocity Range: .0492 to .3936 in./ms (1250 to 9999 meters/sec)

-

Units: English & Metric

-

Measurement Modes:

-

Pulse-Echo (flaws, pits)

-

Echo-Echo (thru-paint)

-

Transducer Types: Dual Element (1 to 10 MHz).

-

Memory: 16 megabit non-volatile ram

-

Memory capacity: 12,000 pages with 1 reading and waveform per page

-

Power Source: Three 1.5V alkaline or 1.2V NiCad AA cells

-

Battery Life: Typically operates for 150 hours on alkaline and 100 hours on NiCad

-

Auto Power off: if idle 5 min

-

Display: 1/8 in. VGA grayscale display 62 x 45.7mm

-

Keyboard: Membrane switch with twelve tactile keys

-

Case: Extruded aluminum body with nickel-plated aluminum end caps (gasket sealed).

-

Operating Temperature: -14° to 140°F (-10° to 60°C)

-

Weight, net: 383 grams

-

Dimensions: 63.5 W x 165 H x 31.5 D mm

-

Warranty: 2 year limited

-

Certification: CE Approved, Factory calibration traceable to national standards

|

|

|